To many, Global Wind Service (GWS), is solely an ISP providing project management and skilled labour for different blade maintenance projects. However, there is more to GWS than meets the eye. We have teamed up with Technical Project Manager, Yu-Huan Lin to help explain, how the utilization of internal engineering capabilities can help solve industry challenges and handle post-warranty blade maintenance.

Utilizing blade engineering skills for industry challenges – GWS’ part of EUDP project CORTIR II

The challenge: Maintaining wind turbine blades is not a simple task. As a wind turbine owner or manufacturer, you can face various challenges when performing structural blade repair on blades that are more than 60 metres long.

The project: Therefore, 26 companies from the wind industry, including GWS, have joined forces to help solve these challenges. The project vision is to ease the decision-making process regarding maintenance and to support the entire value chain on how to minimize risk, as well as operations and maintenance costs. One of the aims is to develop a long-term retrofit solution to repair recurring structural damages on these long blades by removing the root cause.

In the beginning of 2022, GWS delivered a set of test panels which was designed in the project by joint effort of Bladena, DTU and GWS. The panels were then cut into test coupons with waterjet cutting and went through a series of coupon level tests at DTU (Danish Technical University) in Copenhagen. The test results are the fundamental information for the further development of the project.

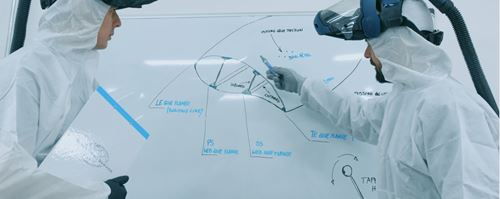

Following this GWS helped preparing the full-scale test blade in the spring. Our team manufactured an aft shear web (jointly designed by DTU, Bladena and GWS) which was mounted the onto the blade. Adding to this the team mounted the steel girder (for loading the blade) onto the blade and reinforced the blade around the loading area. The blade is now undergoing a series of test at DTU.

Engineering capabilities within GWS

All of this (GWS’ contribution to the project) would not have been possible if it had not been for the inhouse engineering capabilities. Having a skilled and well-educated workforce enables GWS to take part in important works as the CORTIR project and to offer help solve different technical issues in collaboration with wind turbine owners and manufacturers.

“Through the utilization of Global Wind Service Academy, GWS has a unique possibility to not only support the industry on a theoretical level but also on a hands-on level. Specially developed workshops have been made, enabling the production and testing of the different solutions” Yu-Huan said.

If you want to know more about GWS’ blade capabilities and knowledge, get in touch with Sales Manager Michal Wilczewski at mw@globalwindservice.com.

For further information on the CORTIR project please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 fmj@bladena.com. A great thanks to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program) for funding the CORTIR Phase 2 project